ADAS recalibration glass is a critical tool for Original Equipment Manufacturer (OEM) repairs, ensuring optimal performance of Advanced Driver Assistance Systems (ADAS) sensors and cameras after damage or replacement. This specialized glass maintains the accuracy of safety features like adaptive cruise control, lane-keeping assist, and automatic emergency braking, enhancing vehicle safety as autonomous driving becomes more common. Installation requires strict best practices, including thorough cleaning, precise cutting, and regular maintenance checks, with technicians trained to meet OEM standards for reliable, safe repairs.

The integration of Advanced Driver-Assistance Systems (ADAS) has transformed modern vehicles, enhancing safety and driving experiences. In original equipment manufacturer (OEM) repairs, the role of ADAS recalibration glass cannot be overstated. This specialized glass is crucial for accurate recalibration, ensuring ADAS features like cameras, sensors, and radars function optimally post-repair. Understanding the unique properties and installation best practices of ADAS recalibration glass is essential for achieving reliable, high-quality OEM repairs in the evolving automotive landscape.

- Understanding ADAS Recalibration Glass: The Key Component in OEM Repairs

- Benefits and Challenges of Using ADAS Recalibration Glass

- Best Practices for Installing and Maintaining ADAS Recalibration Glass in Original Equipment Manufacturer (OEM) Repairs

Understanding ADAS Recalibration Glass: The Key Component in OEM Repairs

ADAS recalibration glass plays a pivotal role in Original Equipment Manufacturer (OEM) repairs, especially with advancements in autonomous driving systems. This specialized glass is designed to ensure that Advanced Driver Assistance Systems (ADAS) sensors and cameras function optimally after a repair or replacement. During vehicle repair, whether it’s due to an accident or regular maintenance, the alignment and calibration of ADAS components become critical for safety and efficiency.

When a car undergoes paintless dent repair or other cosmetic enhancements, precision is key. ADAS recalibration glass helps restore the system’s accuracy by providing a stable and consistent reference point. This is particularly important for features like adaptive cruise control, lane-keeping assist, and automatic emergency braking, which rely on precise sensor data to function correctly. By ensuring proper calibration, this glass contributes to improved vehicle safety and performance in both automotive repair and vehicle repair scenarios.

Benefits and Challenges of Using ADAS Recalibration Glass

The use of ADAS recalibration glass in Original Equipment Manufacturer (OEM) repairs offers significant benefits for both automakers and consumers. This specialized glass plays a critical role in ensuring that Advanced Driver Assistance Systems (ADAS) sensors and cameras function optimally after a fender repair or auto dent repair. By precisely recreating the original optical path, ADAS recalibration glass helps maintain the integrity of safety features like lane departure warning, adaptive cruise control, and automatic emergency braking. This is particularly crucial as autonomous driving capabilities become increasingly integrated into modern vehicles.

However, implementing ADAS recalibration glass also presents challenges. It requires specialized knowledge and equipment to ensure accurate installation. Moreover, not all vehicle models have readily available stock of this specific glass, necessitating custom ordering. Despite these hurdles, the benefits of using ADAS recalibration glass in vehicle repair far outweigh the challenges. It ensures that safety features remain reliable, enhances the overall quality of fender repair and auto dent repair services, and ultimately contributes to a smoother transition towards more autonomous driving experiences.

Best Practices for Installing and Maintaining ADAS Recalibration Glass in Original Equipment Manufacturer (OEM) Repairs

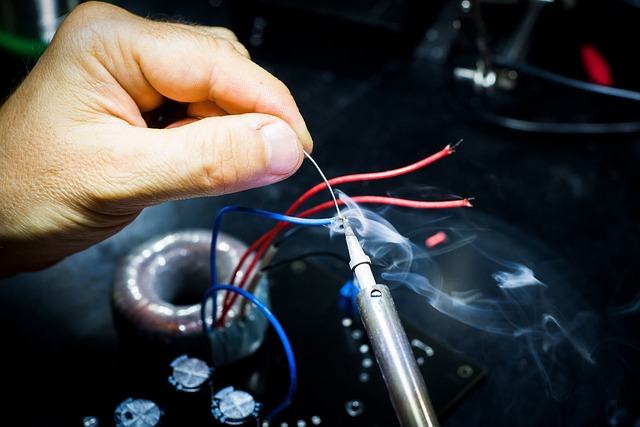

When installing ADAS recalibration glass in OEM repairs, adherence to best practices ensures optimal performance and safety. Firstly, proper preparation is key; this includes ensuring the vehicle’s sensor system is thoroughly cleaned and free from any debris or contaminants that could interfere with calibration. Next, precise measurement and cutting of the glass is essential for a seamless fit within the vehicle’s frame. Technicians should utilize specialized tools and software to ensure accurate alignment of the ADAS sensors after the glass installation. Regular maintenance checks are equally vital; these include periodic inspections for any signs of damage or misalignment, as well as recalibration when necessary, especially after major collision repair center services like fender repair or paintless dent repair.

Additionally, training and certification for technicians handling ADAS recalibration glass are paramount. They must be adept at interpreting sensor data and using diagnostic tools to verify accurate calibration. Staying updated with the latest industry standards and manufacturer guidelines is also crucial in this evolving field of collision repair. This ensures that repairs not only meet OEM specifications but also contribute to the overall safety and reliability of autonomous driving systems.

ADAS recalibration glass plays a pivotal role in ensuring accurate and reliable restoration of original equipment manufacturer (OEM) vehicles equipped with advanced driver-assistance systems (ADAS). By addressing the specific needs of these complex systems, this glass is instrumental in maintaining safety standards and optimal performance. As the use of ADAS technologies continues to grow, the proper installation and maintenance of recalibration glass will be crucial for keeping up with evolving industry demands.